It’s official- we’re only a few months out from delivering our pilot production to New Zealand customers. Production and assembly is all go. To say the team is excited to get bikes to customers is an understatement.

Something we’re keen to share about the progress to build our bikes are a few of the QC (quality control) measures we’ve been taking over the last 6 months as all the parts arrive off the tooling. As you know, quality control and assurance is make or break for most startups and Manta5 have made sure to really focus in on this.

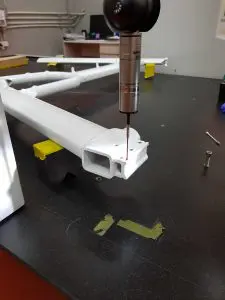

Below are the initial bike frame samples we received being measured on a CMM (coordinate-measuring machine). This machine is a very accurate way to measure objects, and works by measuring the bike frames in comparison to what our engineers modelled. It then tells our production team how far off the frame is in comparison to what we are expecting. This process makes sure that the quality of the product we are receiving from our manufacturers is up to Manta5 standards before we accept them to move forward to develop more frames for our hydrofoil bikes.

Company Update

We’ve been working on a few things lately, starting with the Learn To Ride series. This series will focus on giving you the best tips and tricks we’ve learnt over the years to get up and foiling as fast as possible.

Latest Content – Battery housing tests

Senior Mechanical Engineer, Tim, working through quality checks from a few weeks back around battery testing. You should not be dropping your battery like this when handling it, but at least you know it can handle punishment & that our parts are up to spec.

[gif of Tim dropping battery]

We’ll release more updates as we progress with this pilot production and as our customers receive their bikes.

Cheers,

The Manta5 Team